Pulp Machine

- PRODUCT INDEX

- Pulp Machine

- Application example

Description of Pulp Machine:

This pulp machine is mainly utilized in paper mills, and it consists of double wire former, press section and air drying system. And in the following, more information about them will be given.

1.Double Wire Former:

The double wire former of this pulp making machinery is mainly made up of hydraulic headbox, closed wedge-shaped dewatering machine, pressure dewatering box, wire tensioner, calibration device and cleaner.

2.Press Section:

The press section is mainly composed of vacuum preloading device, suction press device, and wide nip pressure press equipment of high impulse. The structure design of this press section is totally based on the press features of pulp machines so that a better dewatering effect can be obtained.

3.Air Drying System:

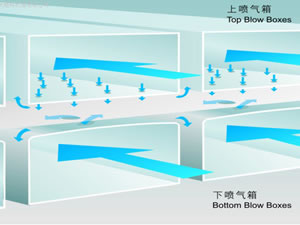

The pulp machine is designed on the basis of floating non-contact drying principle, and multi-layer arrangement mode is designed for its dryers. And the amount of blow boxes and their arrangement depend on the actual productivity.

When the paper sheet is passing the space between the top and bottom blow boxes, it will be dried by the hot air jetted by the two boxes and the air cushion, made by the boxes, is able to support the paper sheet to pass through the space. In addition, the top and bottom blow box can be separated by the cylinder to make the paper guiding and machine cleaning as easy as possible.

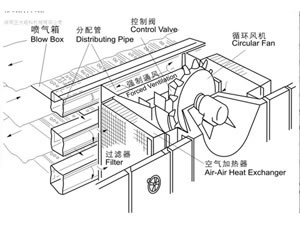

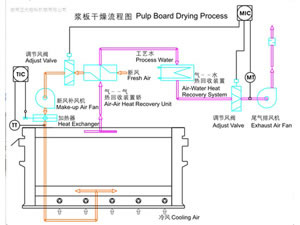

4.External Air Circulation Flow of Air Drying System:

Firstly, to make full use of energy, two-stage heat recovery system has been designed for this kind of pulp machine. The first-stage air-air heat recovery equipment can make use of the hot, wet air from the top of the dryer to preheat the new air, and the preheated new air will be heated to the required temperature via the heater before sent to the bottom of the dryer. Secondly, the second-stage water-air heat recovery unit is capable of heating up the process water and heating water by using the remaining heat of waste gases. Finally, at the bottom of the dryer, there is a set of air supply system used to cool down the pulp board before the board leaves the drying section.

Advantages of Pulp Board Drying Technology:

1.The length of drying section can be shortened to the degree less than the half of normal one, which results in saving construction investment.

2.It is easier to adjust lateral water differences so as to obtain pulp board with even water distribution.

3.The smaller tension, the the pulp board will get in the drying section can make sure the board move more stably, which in turn will largely reduce the number of broken paper sheets.

SHANGHAI LANDYTOP INDUSTRY CO.,LTD is a professional manufacturer of pulp machine in China. Besides pulp machine, we also provide customers worldwide with coater, closed hood and ventilation system, Yankee hood, through air dryer, etc. All of our products have been manufactured strictly according to the ISO9001 quality standards. With high quality and competitive price, our products have been quite popular among customers from Thailand, Indonesia, Vietnam, Japan, Australia, Russia, Azerbaijan, Egypt, Turkey, France, Germany, the United States, Brazil, and so on. If you're interested in our pulp machine, please contact us freely.

- Paper CoaterThe coater, sometimes also referred to as coating machine, is typically designed to improve the surface properties of paper sheet to be smooth and good for printing.

It is mainly comprised of blade coating device and air drying and heating system. And in the following, detailed information about the two components will be discussed....